Nyenzo

| Mwili | Aluminium(5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5% ,3%-3.5%,5%) | ||

| Maliza | Imepozwa | Rangi ya RAL Iliyopigwa | ||

| Mandrel | Alumini ● | Chuma | Chuma cha pua | |

| Maliza | Iliyong'olewa ● | Zinki Iliyowekwa | Imepozwa | |

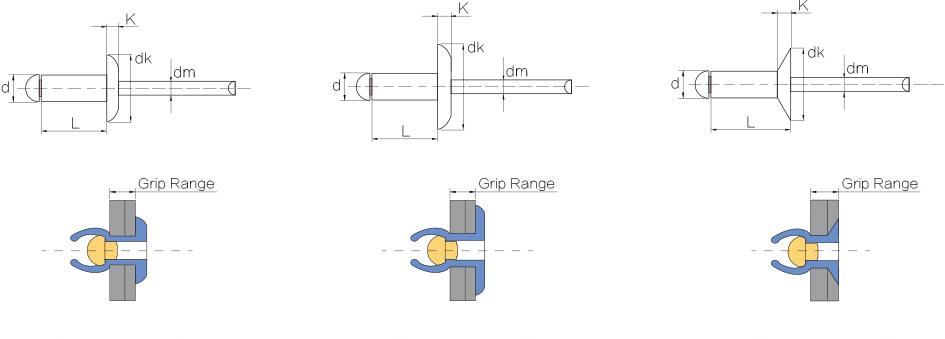

| Aina ya kichwa | Dome, CSK, Flange Kubwa | |||

Vipimo

| D1 NOM. | CHIMBA NO. &UKUBWA WA SHIMO | ART.CODE | UPEO WA KUSHIKAMA | L(MAX) | D NOM. | K MAX. | P MIN. | SHEAR LBS | TENSILE LBS | ||

| INCHI | MM | INCHI | MM | ||||||||

| 3/32" 2.4 mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2 mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0 mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4 mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1,000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Maombi

Alumini yetu kamili ya ncha ya wazi hutumia waya za aloi za ubora wa juu.Baada ya riveting, Haitawahi kutu.ikilinganishwa na rivets za kawaida, kiwango cha rivet ni cha chini, hivyo kinafaa kwa nyenzo zilizounganishwa laini. Rivets za pop za alumini zinaweza kugawanywa katika riveti ya kichwa cha dome, rivets za countersunk na rivet kubwa ya kichwa cha flange. alu mg 2% 2.5% 3.5% na 5% (5052 5154 5056).

Fixpal aina ya wazi ya rivets ya pop ina faida za uendeshaji rahisi, riveting bora, kuonekana nzuri, mali ya juu ya kimwili.Uchaguzi kamili wa rivets za riveting.Alumini za pop zinaweza kutumika sana katika magari mbalimbali, vyombo, utengenezaji wa mashine, umeme, vifaa, mashine za chakula, vifaa vya matibabu, ujenzi, mapambo na maeneo mengine ya kufunga.

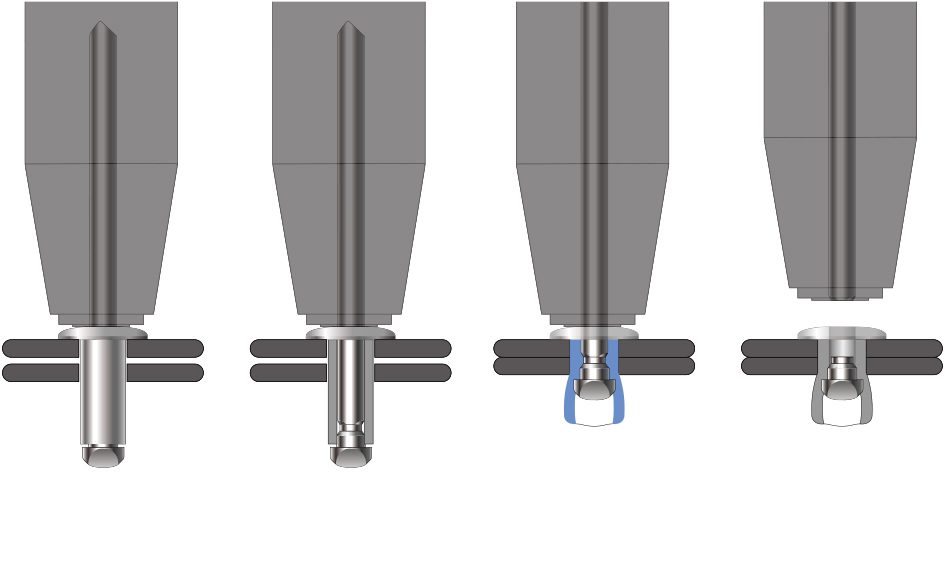

Shida na sababu wakati wa kutumia rivet kipofu:

1. Burrs: Baada ya riveting, mandrel iliyovunjika na burrs hupitia mashimo ya rivet;au mashimo ya riveting yanajitokeza kutoka nje ili kuunda burr ya spatula.

Sababu ya burrs: kipenyo cha mandrel ni ndogo;nyenzo za rivet ni laini;kipenyo cha shimo la kuchimba la workpiece ni kubwa sana;maelezo ya muzzle ya bunduki ya rivet ni kubwa sana;

2. Kichwa cha msumari kinaanguka: Baada ya kuvutwa kwa rivet, kichwa cha msingi cha rivet hakiwezi kufungwa na huanguka kutoka kwenye rivet.

Sababu za kuanguka kwa kichwa cha rivet cha msingi ni: kipenyo cha kofia ya msumari ni kubwa sana;rivet ni fupi, na unene wa rivet haufanani.

3. rivet kupasuka: Baada ya riveting, rivet ni pulsed au kupasuka kabisa.

Sababu za kupasuka kwa rivet ni: ugumu mwingi baada ya riveting annealing au matibabu ya unheated, kofia ya msumari msingi ni kubwa mno.