Nyenzo

| Mwili | Chuma |

| Maliza | Zinki Iliyowekwa |

| Mandrel | Chuma |

| Maliza | Zinki Iliyowekwa |

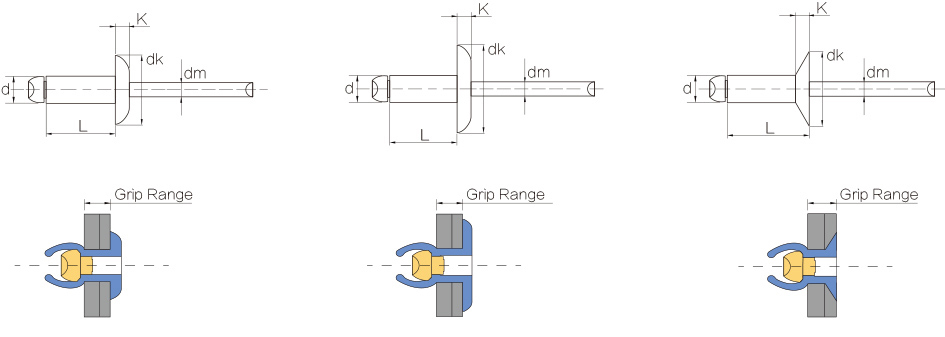

| Aina ya kichwa | Dome, CSK, Flange Kubwa |

Vipimo

| D1 NOM. | CHIMBA NO. &UKUBWA WA SHIMO | ART.CODE | UPEO WA KUSHIKAMA | L(MAX) | D NOM. | K MAX. | P MIN. | SHEAR LBS | TENSILE LBS | ||

| INCHI | MM | INCHI | MM | ||||||||

| 3/32" 2.4 mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2 mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0 mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0.876-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4 mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 1000 4450N | 1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| SS812 | 0.626-0.750 | 15.9-19.1 | 1,000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Maombi

chuma wazi mwisho rivets vipofu si tu urahisi kutumia, ufanisi wa juu, kelele ya chini, inaweza kupunguza nguvu kazi na sifa nyingine, lakini pia uhusiano kifua.Rivets za chuma zinaweza kugawanywa katika rivet ya kichwa cha dome, rivets za countersunk na rivet kubwa ya kichwa cha flange.Nguvu ya mvutano na ya kukata ya rivets za vipofu vya chuma ni kubwa zaidi kuliko riveti za kawaida za alumini.Inatumika sana katika viwanda, inaweza kukidhi mahitaji ya ombi la nguvu kubwa.

Shida na sababu wakati wa kutumia pop rivet:

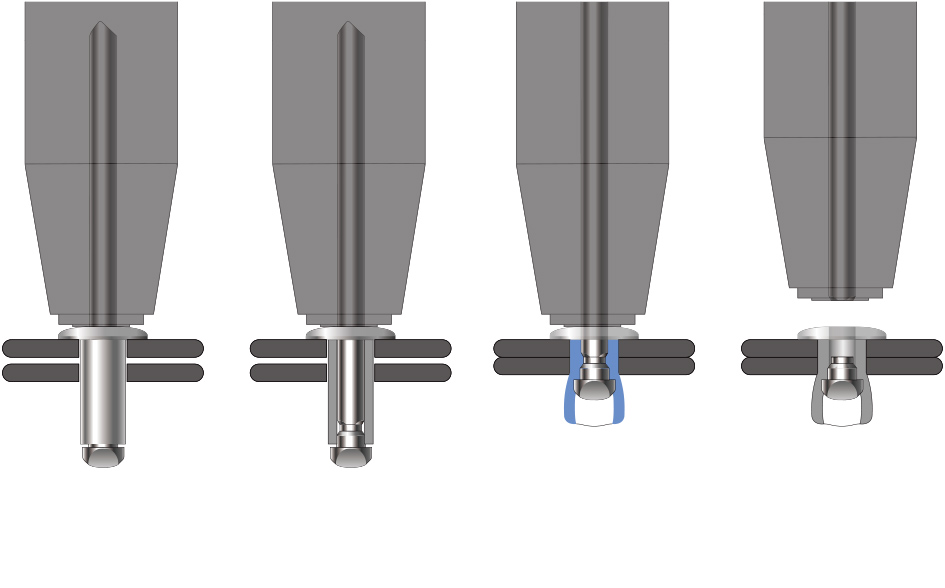

4.Mchoro wa pop huvutwa kupitia: Mandrel ya rivet hutolewa kabisa kutoka kwa rivet, na mandrel imevunjwa.Baada ya riveting, kuondoka mashimo tupu katika rivet.

Sababu za kuvuta ni: mvutano mwingi wa rivet mandrel;kipenyo kidogo cha kofia za mandrel;vifaa vya riveting laini;uso wa shimo la ndani ni lubricated sana.

5.Kichwa cha kuruka au ngoma haitoshi: Wakati wa kuvuta rivets, msingi wa rivet hujitokeza kabisa, au rivet haina kuvimba.

Sababu za jambo hili ni: udhibiti wa nguvu ya mvutano ni mdogo sana wakati msingi wa msumari unafanywa;mwili wa riveting ni wa juu (annealing isiyo na usawa);

6. Kupumzika baada ya riveting: Baada ya riveting, mwili riveting ni huru katika shimo workpiece.